February 8, 2019 To: IIAR Members Re: Fourth (4th) Public Review of Standard BSR/IIAR 2-2014, Addendum A, Standard for Safe design of Closed-Circuit Ammonia Refrigeration Systems. A fourth (4th) public review of draft standard BSR/IIAR 2-2014 Addendum A, Standard for Safe Design of Closed-Circuit Ammonia Refrigeration Systems is now open. The International Institute of Ammonia Refrigeration (IIAR) invites you to make comments on the draft standard. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary.

BSR/IIAR 2-2014, Addendum A specifies the minimum safety criteria for design of closed-circuit ammonia refrigeration systems. It presupposes that the persons who use the document have a working knowledge of the functionality of ammonia refrigerating system(s) and basic ammonia refrigerating practices and principles. This standard is intended for those who develop, define, implement and/or review the design of ammonia refrigeration systems. This standard shall apply only to closed-circuit refrigeration systems utilizing ammonia as the refrigerant. It supplements existing general refrigeration standards issued by IIAR and other organizations such as ASHRAE, ASME, and ANSI. It is not intended to supplant existing safety codes (e.g., model mechanical or fire codes).

IIAR has designated the revised standard as BSR/IIAR 2-2014, Addendum A. Upon approval by the ANSI Board of Standards Review, the standard will receive a different name that reflects this approval date.

We invite you to participate in the fourth (4th) public review of BSR/IIAR 2-2014, Addendum A. IIAR will use the American National Standards Institute (ANSI) procedures to develop evidence of consensus among affected parties. ANSI’s role in the revision process is to establish and enforce standards of openness, balance, due process and harmonization with other American and International Standards. IIAR is the ANSI-accredited standards developer for BSR/IIAR 2-2014, Addendum A, and is responsible for the technical content of the standard.

This site includes links to the following attachments:

The 30-day public review period will be from February 8, 2019 to March 10, 2019. Comments are due no later than March 10, 2019.

Thank you for your interest in the public review of BSR/IIAR 2-2014, Addendum A, Standard for Safe Design of Closed-Circuit Ammonia Refrigeration Systems.

Tag: RAGAGEP (Page 2 of 3)

A little over a year ago, our Process Safety Engineer, Josh Latovich, posted an article entitled “The Cyrus Shank LQ Series Relief Valves – A Discussion on Manufacturer’s Recommendations and the 5 Year Pressure Relief Valve Interval.” The article dealt with confusion surrounding dueling RAGAGEP’s for the replacement interval of hydrostatic valves.

Since that time the issue has come up repeatedly with various opinions provided by industry organizations, end-users, OSHA & EPA inspectors and others. In an October 10th, 2017 update to the article to say “If the Cyrus Shank engineering department changes their position then this issue can be re-evaluated…”

Well, GOOD NEWS. At the 2018 RETA Conference in Dallas, TX this week I was lucky enough to get to spend some time with Cyrus Shank engineer Matt Powell. He was willing to discuss the issue and provide assistance to resolve this issue. Here’s what we need from Cyrus Shank regarding this issue:

This means that the manufacturer is onboard with the IIAR’s position on NOT having to replace these valves if they are visually inspected.

THAT SAID, you still need to look at the FUNCTION of these valves in your system during your Process Hazard Analysis (PHA) to see if their failure will negatively impact your system. In the way they are NORMALLY used, a failure of these valves would cause efficiency issues, rather than safety ones. But you will need to look at the unique situation you have with them before deciding whether a replacement schedule is appropriate or not.

Thanks again to Matt Powell and Cyrus Shank for finally putting this issue to rest. You can download a copy of the letter from them at this link.

For a full recap of the issue, you can go to the original article.

The IIAR’s Standard 5 Startup of Closed-Circuit Ammonia Refrigeration Systems is often overlooked. They’ve just announced a public review of an updated version of the standard. No changelog was provided, but it looks like a fairly minor 5yr maintenance update at first glance.

To: IIAR Members Re: First (1st) Public Review of BSR/IIAR 5-201x, Startup of Closed-Circuit Ammonia Refrigeration Systems A first (1st) public review of draft standard BSR/IIAR 5-201x, Startup of Closed-Circuit Ammonia Refrigeration Systems is now open. The International Institute of Ammonia Refrigeration (IIAR) invites you to make comments on the draft standard. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary. BSR/IIAR 5-201x, defines the minimum requirements for startup of closed-circuit ammonia refrigeration systems. It presupposes that the persons who use the document have a working knowledge of the functionality of an ammonia refrigeration system(s) and basic ammonia refrigeration practices and principles. This standard is intended for those who startup closed-circuit ammonia refrigeration systems. This standard shall apply only to stationary closed-circuit refrigeration systems utilizing ammonia as the refrigerant. It supplements existing general refrigeration standards issued by IIAR and other organizations such as ASHRAE, ASME, and ANSI. It is not intended to supplant existing safety codes (e.g., model mechanical or fire codes).

IIAR has designated the draft standard as BSR/IIAR 5-201x. Upon approval by the ANSI Board of Standards Review, the standard will receive a different name that reflects this approval date.

We invite you to participate in the first (1st) public review of BSR/IIAR 5-201x. IIAR will use the American National Standards Institute (ANSI) procedures to develop evidence of consensus among affected parties. ANSI’s role in the revision process is to establish and enforce standards of openness, balance, due process, and harmonization with other American and International Standards. IIAR is the ANSI-accredited standards developer for BSR/IIAR 5-201x, and is responsible for the technical content of the standard.

This site includes links to the following attachments:

The 45-day public review period will be from October 26th, 2018 through December 10th, 2018. Comments are due no later than 5:00 pm Eastern Standard Time (EST) on December 10th, 2018.

The IIAR has announced a 3rd Public Review of Standard BSR/IIAR 2-2014, Addendum A, Standard for Safe design of Closed-Circuit Ammonia Refrigeration Systems. This brings some interesting changes to IIAR 2 . Two of these proposed changes are :

- Clearing up the “corrosion allowance” debate in a way that most reasonable people can live with.

- Clearing up the NH3 detection requirements – mostly by moving Level 2 & 3 to the informative appendix.

For more information, check out the announcement (with links) below:

A third (3rd) public review of draft standard BSR/IIAR 2-2014 Addendum A, Standard for Safe Design of Closed-Circuit Ammonia Refrigeration Systems is now open. The International Institute of Ammonia Refrigeration (IIAR) invites you to make comments on the draft standard. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary.

BSR/IIAR 2-2014, Addendum A specifies the minimum safety criteria for design of closed-circuit ammonia refrigeration systems. It presupposes that the persons who use the document have a working knowledge of the functionality of ammonia refrigerating system(s) and basic ammonia refrigerating practices and principles. This standard is intended for those who develop, define, implement and/or review the design of ammonia refrigeration systems. This standard shall apply only to closed-circuit refrigeration systems utilizing ammonia as the refrigerant. It supplements existing general refrigeration standards issued by IIAR and other organizations such as ASHRAE, ASME, and ANSI. It is not intended to supplant existing safety codes (e.g., model mechanical or fire codes).

IIAR has designated the revised standard as BSR/IIAR 2-2014, Addendum A. Upon approval by the ANSI Board of Standards Review, the standard will receive a different name that reflects this approval date.

We invite you to participate in the third (3rd) public review of BSR/IIAR 2-2014, Addendum A. IIAR will use the American National Standards Institute (ANSI) procedures to develop evidence of consensus among affected parties. ANSI’s role in the revision process is to establish and enforce standards of openness, balance, due process and harmonization with other American and International Standards. IIAR is the ANSI-accredited standards developer for BSR/IIAR 2-2014, Addendum A, and is responsible for the technical content of the standard.

This site includes links to the following attachments:

.

The 30-day public review period will be from October 5, 2018 to November 4, 2018. Comments are due no later than November 4, 2018.

Thank you for your interest in the public review of BSR/IIAR 2-2014, Addendum A, Standard for Safe Design of Closed-Circuit Ammonia Refrigeration Systems.

The October 17th, 2017 Ammonia release in Fernie, BC resulted in three fatalities:

On October 16, 2017, the curling brine chiller at the Fernie Memorial Arena was put back into operation after a seasonal shutdown. During the shutdown and seasonal maintenance, ammonia had been detected in the curling brine system, indicating that the curling brine chiller was leaking… A total of three people were found deceased in the mechanical room: the director of leisure services, the refrigeration operator, and a refrigeration contractor mechanic.

Three people died in a completely avoidable incident. If you want to know the particulars of the incident, I’d recommend you go read the Incident Report itself. While we can’t go back in time and avoid this particular incident, we can extract some valuable lessons from it to prevent a similar incident in the future.

There’s a lot that went wrong, but we’re going to focus on a few key failures in Mechanical Integrity, Process Safety, and Release / Incident Response. We’ll briefly discuss each failure and provide ten opportunities for improving your current Process Safety system.

Note: While this incident occurred in Canada, which does not have robust Process Safety regulation, we’re going to provide our analysis as if it was a PSM/RMP plant. Even if this incident had occurred in the US, the total system inventory was estimated at less than 1,000 pounds, placing it in the General Duty category. Most operators of these General Duty systems do not choose to implement a PSM system – hopefully this incident will cause them to re-evaluate that choice.

Equipment Age and installation: In 2011, the facility received a recommendation from their mechanical contractor to replace the chiller due to its age. It had been in service for about 24 years and had a life expectancy of 20-25yrs. (At the time of failure the chiller was in service for approximately 31yrs.) The facility actually budgeted for this replacement, deferred it, and then dropped the idea altogether. The report (and appendices) detail this decision making and indicates that the people making these decisions didn’t understand the underlying safety issues or the possible repercussions of these decisions. In part this was due to management turnover – the people who received the initial recommendation no longer worked at the facility when those recommendations were due to be implemented. Additionally, post-release, it was determined that the failed coupling was not properly supported.

Possible PSM citations: 1910.119(d)(3)(ii) for not installing the coupling per the manufacturers recommendations. 1910.119(d)(3)(ii) for equipment operating outside manufacturer’s recommended lifespan. 1910.119(e)(1) for the PHA not analyzing the hazards associated with operating outside the manufacturer’s recommended lifespan. 1910.119(j)(5) for operating the equipment with a known (service life) deficiency without assuring safe operation. 1910.119(m)(5) for not addressing and resolving a recommendation. (if the recommendation was made due to an indication of NH3 in the brine)

Opportunity #1: When a piece of equipment has a stated service life, you need to either replace the equipment per the recommendation or support your decision to keep it in service with a suitable engineering rationale.

Opportunity #2: When operators & contractors make recommendations, they need to provide CLEAR and defensible reasons for those recommendations.

Opportunity #3: When recommendations are delayed, deferred, or not completed, the operators & contractors need to ensure that the decision makers understand the implications of their decisions.

Opportunity #4: A Pre-Startup Safety Review (PSSR) and ongoing MI tasks need to ensure that equipment is installed correctly and maintained in a safe manner / arrangement.

Signs of Failure and Deficiency Response: The facility detected NH3 in the brine (by scent) in April of 2017 and then followed it up with a lab test of the brine showing over 3,000ppm of NH3 in June. The facility decided to continue operating the chiller and “monitor” it. A second test in August showed an NH3 concentration near 2,000ppm. Again, the facility decided to keep “monitoring” the situation. The report indicated that the personnel performing the tests and receiving the results didn’t understand the safety implications of them. Even after receiving the tests showing the chiller had failed, the facility decided to keep operating it. According to the report, there was no evidence the facility understood the hazards associated with a leaking chiller.

Furthermore, due to a miscommunication, the contractor believed the facility had taken the chiller out-of-service and they were preparing a bid to replace the leaking unit. The contractor’s recommendation to “monitor” the unit was likely meant to monitor it to see if the valves were leaking by, but the facility interpreted it as a go-ahead to continue operating the defective chiller until it could be replaced as long as they “monitored” it.

The contractor had no policy or procedure in place to deal with a failed chiller outside the usual troubleshooting, repair and replace activities. The investigators concluded that none of the people involved with the decision to continue operating the chiller had training or qualifications involving condition/risk assessment.

Possible PSM citations: 1910.119(j)(5) for operating the equipment with a known (integrity) deficiency without assuring safe operation. 1910.119(m)(5) for not addressing and resolving a recommendation. 1910.119(g)(1)(i) for not training personnel of the hazards associated with a leaking chiller.

Opportunity #5: Personnel reviewing test results need to understand the meaning of the test results and the safety implication of those test results.

Opportunity #6: When test results are provided to decision-makers, these results need to provide adequate information so that the decision-makers understand them and their safety implications.

Opportunity #7: When contractors are called to deal with deficient equipment, they will almost always provide guidance / estimates on how to repair / replace the equipment, but facilities should demand a risk assessment on continued operation of the equipment if they intend to continue its operation while planning and preparing for the repair / replacement.

From Appendix V of the report: “In the majority of instances, owner/operators relied heavily on the refrigeration contractor’s assessment of the equipment and evaluation of the NH3 indication in the brine samples. The owner is accountable for the safe condition and operation of the equipment but in some instances, deferment to the refrigeration contractor’s assessment and recommendations for the equipment was observed.”

Opportunity #8: When a facility outsources maintenance work, they often erroneously think that they are outsourcing the responsibility as well. It is important for a facility to understand that this remains their process and their responsibility. Ask tough questions of your contractors to ensure that you understand the condition of your system.

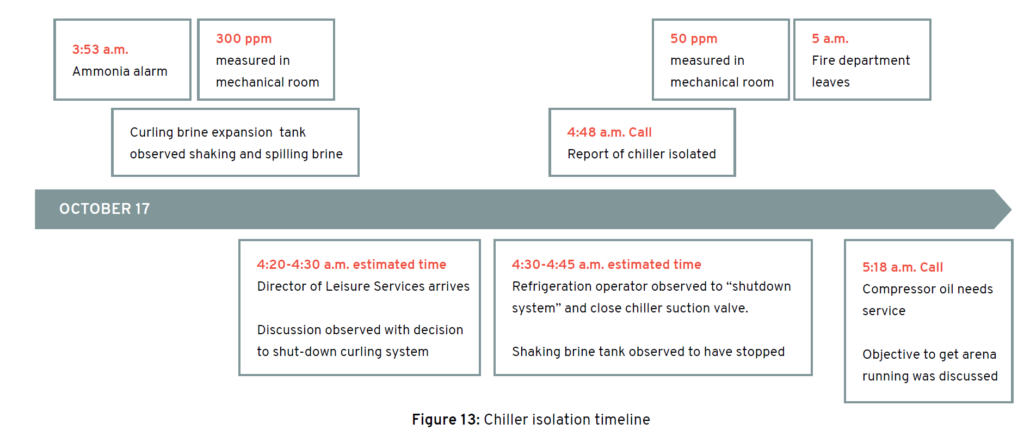

Facility and Contractor Incident Release Response: On the day of the release at 03:53 the machine room NH3 alarm registered 300ppm. Responding facility personnel observed the brine expansion tank shaking and spilling brine. At 04:30, the facility personnel shutdown the system and closed the chiller suction valve, observing that the shaking in the brine tank stopped. This should have indicated to the facility personnel that the separation between the brine and NH3 sides was completely compromised and that the brine loop was now full of ammonia. At 05:18 the facility personnel called the contractor to come in and re-configure the system to operate without the brine chiller.

At some point during the work, the personnel isolated the brine chiller, trapping the ammonia-laden brine in the chiller with no outlet available for it. As this ammonia-laden brine warmed up, the pressure inside the brine chiller rose and, at an estimated pressure of 30-150psig, a coupling on the brine-side of the brine chiller failed releasing the contents into the machine room and onto the personnel in the room. The estimated total NH3 release was 22 pounds (9lbs immediately vaporizing) resulting in an immediate concentration in the area of 20,000ppm which dissipated to about 5,000ppm over a period of 5 minutes.

The report uses electricity demand to conclude that the personnel did not attempt a pump-out of the brine chiller. Unlike a CSB report, the report does not go into the fatalities. We have no idea where the personnel were positioned in the room, or what – if any – PPE they were wearing at the time of the release. It can reasonably be surmised that they weren’t wearing any respiratory PPE at all.

Possible PSM citations: 1910.119(g)(1)(i) for not training personnel of the hazards associated with NH3 contaminated brine and the hazards of trapping it. 1910.119(h)(3)(ii) for the contractor not being trained in the hazards associated with NH3 contaminated brine and 1910.119(h)(2)(v) for the facility not ensuring this training occurred. 1910.119(n) for not providing “procedures to handle small releases.” 1910.119(f)(1)(i)(D) for not providing an emergency shutdown procedure. 1910.119(f)(1)(i)(E) for not providing an emergency operations procedure.

Opportunity #9: While we often train on the dangers associated with trapping NH3, the dangers of trapping NH3 contamination in a secondary loop is rarely discussed. Operator training in facilities that utilize secondary cooling loops must address contamination and its possible safety implications.

Opportunity #10: While it’s not possible to know for sure, it is extremely likely that all three of these fatalities could have been avoided if the personnel were wearing full-face APRs at the time of release. Note: They would have to have been wearing them, not have them “near-by.” APR’s aren’t magic.

090618 Update: Full WorkSafeBC Incident Report

IIAR 6 continues its development. This document will replace IIAR Bulletin 110 (among others) and will be very important. The current review only lists changes since Public Review #2.

| To: | IIAR Members |

| Re: | Third (3rd) Public Review of Standard BSR/IIAR 6-201x, Standard for Inspection, Testing, and Maintenance of Closed-Circuit Ammonia Refrigeration Systems. |

| A third (3rd) public review of draft standard BSR/IIAR 6-201x, Standard for Inspection, Testing, and Maintenance of Closed-Circuit Ammonia Refrigeration Systems is now open. The International Institute of Ammonia Refrigeration (IIAR) invites you to make comments on the draft standard. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary.

BSR/IIAR 6-201x, specifies the minimum requirements for inspection, testing, and maintenance applicable to stationary closed-circuit ammonia refrigeration systems. It presupposes that the persons who use the document have a working knowledge of the functionality of ammonia refrigeration system(s) and basic ammonia refrigeration practices and principles. This standard is intended for those who inspect, test, and maintain stationary closed-circuit ammonia refrigeration systems. This standard shall apply only to stationary closed-circuit refrigeration systems utilizing ammonia as the refrigerant. It supplements existing general refrigeration standards issued by IIAR and other organizations such as ASHRAE, ASME, and ANSI. It is not intended to supplant existing safety codes (e.g., model mechanical or fire codes). IIAR has designated the draft standard as BSR/IIAR 6-201x. Upon approval by the ANSI Board of Standards Review, the standard will receive a different name that reflects this approval date. We invite you to participate in the third (3rd) public review of BSR/IIAR 6-201x. IIAR will use the American National Standards Institute (ANSI) procedures to develop evidence of consensus among affected parties. ANSI’s role in the revision process is to establish and enforce standards of openness, balance, due process and harmonization with other American and International Standards. IIAR is the ANSI-accredited standards developer for BSR/IIAR 6-201x and is responsible for the technical content of the standard. This site includes links to the following attachments: The 45-day public review period will be from July 6th, 2018 through August 20th, 2018. Comments are due no later than 5:00 pm Eastern Standard Time (EST) on August 20th, 2018. Thank you for your interest in the public review of BSR/IIAR 6-201x, Standard for Inspection, Testing, and Maintenance of Closed-Circuit Ammonia Refrigeration Systems. |

|

| To: | IIAR Members |

| Re: | Second (2nd) Public Review of Standard BSR/IIAR 2-2014, Addendum A, Standard for Safe design of Closed-Circuit Ammonia Refrigeration Systems. |

|

A second (2nd) public review of draft standard BSR/IIAR 2-2014 Addendum A, Standard for Safe Design of Closed-Circuit Ammonia Refrigeration Systems is now open. The International Institute of Ammonia Refrigeration (IIAR) invites you to make comments on the draft standard. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary. BSR/IIAR 2-2014, Addendum A specifies the minimum safety criteria for design of closed-circuit ammonia refrigeration systems. It presupposes that the persons who use the document have a working knowledge of the functionality of ammonia refrigerating system(s) and basic ammonia refrigerating practices and principles. This standard is intended for those who develop, define, implement and/or review the design of ammonia refrigeration systems. This standard shall apply only to closed-circuit refrigeration systems utilizing ammonia as the refrigerant. It supplements existing general refrigeration standards issued by IIAR and other organizations such as ASHRAE, ASME, and ANSI. It is not intended to supplant existing safety codes (e.g., model mechanical or fire codes). IIAR has designated the revised standard as BSR/IIAR 2-2014, Addendum A. Upon approval by the ANSI Board of Standards Review, the standard will receive a different name that reflects this approval date. We invite you to participate in the second (2nd) public review of BSR/IIAR 2-2014, Addendum A. IIAR will use the American National Standards Institute (ANSI) procedures to develop evidence of consensus among affected parties. ANSI’s role in the revision process is to establish and enforce standards of openness, balance, due process and harmonization with other American and International Standards. IIAR is the ANSI-accredited standards developer for BSR/IIAR 2-2014, Addendum A, and is responsible for the technical content of the standard. This site includes links to the following attachments:

The 45-day public review period will be from March 23, 2018 to May 7, 2018. Comments are due no later than May 7, 2018. |

|

IIAR has just announced that two standard’s revisions are available for public review and comment: IIAR 6 & IIAR 7.

IIAR 6 is a new standard. In our opinion, it is going to be the largest change to NH3 Refrigeration practices since the advent of the PSM/RMP rules. Among other things, it is meant to replace IIAR Bulletin 109 (IIAR Minimum Safety Criteria for a Safe Ammonia Refrigeration System) and IIAR Bulletin 110 (Guidelines for: Start-Up, Inspection and Maintenance of Ammonia Mechanical Refrigerating Systems)

Here is some info from the IIAR:

IIAR 6 (Maintenance) Public Review #2

A second (2nd) public review of draft standard BSR/IIAR 6-201x, Standard for Inspection, Testing, and Maintenance of Closed-Circuit Ammonia Refrigeration Systems is now open. The International Institute of Ammonia Refrigeration (IIAR) invites you to make comments on the draft standard. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary.

BSR/IIAR 6-201x, specifies the minimum requirements for inspection, testing, and maintenance applicable to stationary closed-circuit ammonia refrigeration systems. It presupposes that the persons who use the document have a working knowledge of the functionality of ammonia refrigeration system(s) and basic ammonia refrigeration practices and principles. This standard is intended for those who inspect, test, and maintain stationary closed-circuit ammonia refrigeration systems. This standard shall apply only to stationary closed-circuit refrigeration systems utilizing ammonia as the refrigerant. It supplements existing general refrigeration standards issued by IIAR and other organizations such as ASHRAE, ASME, and ANSI. It is not intended to supplant existing safety codes (e.g., model mechanical or fire codes).

IIAR has designated the draft standard as BSR/IIAR 6-201x. Upon approval by the ANSI Board of Standards Review, the standard will receive a different name that reflects this approval date.

We invite you to participate in the second (2nd) public review of BSR/IIAR 6-201x. IIAR will use the American National Standards Institute (ANSI) procedures to develop evidence of consensus among affected parties. ANSI’s role in the revision process is to establish and enforce standards of openness, balance, due process and harmonization with other American and International Standards. IIAR is the ANSI-accredited standards developer for BSR/IIAR 6-201x and is responsible for the technical content of the standard.

This site includes links to the following attachments:

- Background information on BSR/IIAR 6-201x,

- Public Review Announcement,

- Public Review Draft,

- On-line Comment Form for BSR/IIAR 6-201x

The 45-day public review period will be from March 2nd, 2018 through April 16th, 2018. Comments are due no later than 5:00 pm Eastern Standard Time (EST) on April 16th, 2018.

Note: The changes in IIAR 6 PR2 are fairly large and will require you to review your MI program for compliance.

.

IIAR 7 has been around for a while. Early last year we made some significant changes to our templates to be compliant with its unique requirements.

IIAR 7 (Operating Procedures) Public Review #2

A second (2nd) public review of draft standard BSR/IIAR 7-201x, Developing Operating Procedures for Closed-Circuit Ammonia Refrigeration Systems is now open which presents substantive changes only that were received and approved during the standard’s first (1st) public review and comment response resolutions. The International Institute of Ammonia Refrigeration (IIAR) invites you to make comments on the draft standard. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary.

BSR/IIAR 7-201x, defines the minimum requirements for developing operating procedures applicable to closed-circuit ammonia refrigeration systems. It presupposes that the persons who use the document have a working knowledge of the functionality of an ammonia refrigeration system(s) and basic ammonia refrigeration practices and principles. This standard is intended for those who develop, define, or review operating procedures, or a combination thereof, for closed-circuit ammonia refrigeration systems. This standard shall apply only to stationary closed-circuit refrigeration systems utilizing ammonia as the refrigerant. It supplements existing general refrigeration standards issued by IIAR and other organizations such as ASHRAE, ASME, and ANSI. It is not intended to supplant existing safety codes (e.g., model mechanical or fire codes).

IIAR has designated the draft standard as BSR/IIAR 7-201x. Upon approval by the ANSI Board of Standards Review, the standard will receive a different name that reflects this approval date.

We invite you to participate in the second (2nd) public review of BSR/IIAR 7-201x. IIAR will use the American National Standards Institute (ANSI) procedures to develop evidence of consensus among affected parties. ANSI’s role in the revision process is to establish and enforce standards of openness, balance, due process, and harmonization with other American and International Standards. IIAR is the ANSI-accredited standards developer for BSR/IIAR 7-201x and is responsible for the technical content of the standard.

This site includes links to the following attachments:

- Background information on BSR/IIAR 7-201x,

- Public Review Announcement,

- Public Review Draft,

- On-line Comment Form for BSR/IIAR 7-201x

The 30-day public review period will be from March 2nd, 2018 through April 1st, 2018. Comments are due no later than 5:00 p.m. Eastern Standard Time (EST) on April 1st, 2018.

Note: The changes in IIAR 7 PR2 are fairly minor and are unlikely to substantially affect your SOPs if you are already compliant with IIAR 7-2013.

OSHA’s published CPL-03-00-021 – “PSM Covered Chemical Facilities National Emphasis Program” includes an example document request list that often correlates fairly well to the one that OSHA inspectors provide during an NEP inspection. Below, I’ll outline how programs using our PSM system can answer those requests with PSM documents.

Table 1 – Documents That Should Be Requested Prior to Identifying the Selected Unit(s)

OSHA 300 logs for the previous three years for the employer and the process-related contractors*.

Documents regarding your OSHA 300 logs should be kept by your Safety Department. This is addressed in your Contractor Element Written Plan for the contractor and it’s likely your Safety Department.

All contract employee injury and illness logs as required by 1910.119(h)(2)(vi)*.

Most NH3 Refrigeration PSM facilities handle this with the contractor’s OSHA 300 logs.

A list of all PSM-covered process/units in the complex.

The vast majority of NH3 Refrigeration PSM facilities have a single covered process in the complex. If you have multiple processes on the same site, you likely handle / explain this fairly well in your RMP Hazard Assessment documentation.

A list of all units and the maximum intended inventories* of all chemicals (in pounds) in each of the listed units. Compliance Guidance: 1910.119(d)(2)(i)(C) requires employers to have process safety information (PSI) for the maximum intended inventories of chemicals that are part of their PSM-covered processes.

The inventory of the covered process(es) is in the PSI directory in a spreadsheet that shows the Inventory Calculation. Documentation regarding the Maximum Intended Inventory is handled in the PSI Element Written Plan.

A summary description of the facility’s PSM program.

The RMP Element Written Plan includes this information in general – individual Elements have information concerning that element in the Element Written Plan. Showing the inspectors the procedural sections in the RMP entitled “Implementation Policy: Risk Management Prevention Plan” & “Implementation Policy: Management of Program Activities” has generally been more than sufficient to answer this question.

Unit process flow diagrams*.

Most NH3 Refrigeration PSM facilities handle this in the P&ID’s – possibly in conjunction with a Block Flow or Mass & Energy Balance.

Process narrative descriptions.

This is addressed in the beginning of the System ROSOP as well as in the individual equipment RESOPs.

Host employer’s program for evaluating contract employer’s safety information.

This is addressed in your Contractor Element Written Plan. Your documented use of forms CQ1-CQ4 should provide adequate information to answer the question.

Host employer’s program/safe work practices for controlling the entrance/exit/work of contractors and their workers in covered process areas.

This is addressed in your Contractor Element Written Plan. Likely, it redirects you to the facility Safety / Risk Management policies.

Emergency Action Plan* (If the employer has 10 or fewer employees they may communicate the plan orally (29 CFR 1910.38(b)) — i.e., they may not have a written emergency action plan; and Emergency Response Plan* if the facility is also required to comply with 29 CFR 1910.120(q).

This is generally handled by your Safety Department as it is a “general industry” requirement.

Host employer’s program for periodically evaluating contractor performance.

This is addressed in your Contractor Element Written Plan. Your documented use of form CQ6 should provide adequate information to answer the question.

Table 2 – Documents That Should Be Requested After the Selected Unit(s) Are Identified

Piping and instrumentation diagrams (P&IDs) including legends*.

Your P&ID collection will include title sheets that satisfy the requirement for legends.

Unit electrical classification documents*.

The vast majority of NH3 Refrigeration PSM facilities cover this in a stand-alone letter provided in the PSI directory. That letter will reference your IIAR RAGAGEP stating that the system is “unclassified” or an “ordinary location.” Your electrical classification is contingent on an accurate and compliant Ventilation calculation which should be in your PSI directory.

Descriptions of safety systems (e.g., interlocks, detection or suppression systems)*.

Safety systems (e.g., interlocks, detection or suppression systems) are covered in each individual RESOP for each individual piece of equipment.

Design codes and standards employed for process and equipment in the Selected Unit(s).

The vast majority of NH3 Refrigeration PSM facilities cover this in a stand-alone letter provided in the PSI directory. That letter will document which RAGAGEP you’ve chosen and it also provides a place for you to certify it.

A list of all workers (i.e., hourly and supervisory) presently involved in operating the Selected Units(s), including names, job titles, work shifts, start date in the unit, and the name of the person(s) to whom they report (their supervisor).

This information should be captured in the individual operator OT1 forms in the Training Element directory. You may have to supplement the OT1 forms with information from your HR department.

The initial process hazard analysis*(PHA) and the most recent update/redo or revalidation* for the Selected Unit (s); this includes PHA reports*, PHA worksheets*, actions to address findings and recommendations promptly*, written schedules for actions to be completed*, and documentation of findings and recommendations*. Compliance Guidance: Any PHA performed after May 25, 1987 that meets the requirements of 1910.119(e) may be claimed by the employer as the initial PHA for compliance purposes, see 1910.119(e)(1)(v).

The PHA is located in the Process Hazard Analysis directory. It is not generally our custom to “revalidate” PHA’s but to complete a new PHA (compliant with the IIAR Compliance Guidelines questions) during the 5yr “revalidation.”

Safe upper and lower operating limits for the Selected Unit(s)*.

Safe upper and lower operating limits are covered in each individual RESOP for each individual piece of equipment.

A list by title and unit of each PSM incident report; all PSM incident reports for the Selected Unit*.

Generally speaking, the Incident Investigations aren’t sorted by unit, but providing all the Incident Investigations that have been created over the document request period should suffice.

Contract employer’s safety information and programs (this will be requested from the host employer after it is determined which contractor(s) will be inspected).

This is addressed in your Contractor Element Written Plan. Your documented use of forms CQ1-CQ4 should provide some information to answer the question. In facilities that allow contractors to provide their own Safety Programs, you will need to be able to provide those programs as well as your evaluation of them. The vast majority of NH3 Refrigeration PSM facilities do not allow contractors to use their own Safety Programs – instead requiring them to use the established facility Safety Programs.

Contractor employer’s documentation of contract workers’ training, including the means used to verify employees’ understanding of the training* (this will be requested from the respective contractor employer(s) after it is determined which contractor(s) will be inspected).

This is addressed in your Contractor Element Written Plan. Your documented use of forms CQ3-CQ4 should provide adequate information to answer the question.

Note: This older Post provides additional questions from a recent NEP inspection.

If you need help preparing for, managing, or dealing with the aftermath of an OSHA or EPA inspection, please contact us.

| November 10th, 2017 | |

| To: | IIAR Members |

| Re: | First (1st) Public Review of Standard BSR/IIAR 7-201x, Developing Operating Procedures for Closed-Circuit Ammonia Refrigeration Systems. |

| A first (1st) public review of draft standard BSR/IIAR 7-201x, Developing Operating Procedures for Closed-Circuit Ammonia Refrigeration Systems is now open. The International Institute of Ammonia Refrigeration (IIAR) invites you to make comments on the draft standard. Substantive changes resulting from this public review will also be provided for comment in a future public review if necessary.

BSR/IIAR 7-201x, defines the minimum requirements for developing operating procedures applicable to closed-circuit ammonia refrigeration systems. It presupposes that the persons who use the document have a working knowledge of the functionality of an ammonia refrigeration system(s) and basic ammonia refrigeration practices and principles. This standard is intended for those who develop, define, or review operating procedures, or a combination thereof, for closed-circuit ammonia refrigeration systems. This standard shall apply only to stationary closed-circuit refrigeration systems utilizing ammonia as the refrigerant. It supplements existing general refrigeration standards issued by IIAR and other organizations such as ASHRAE, ASME, and ANSI. It is not intended to supplant existing safety codes (e.g., model mechanical or fire codes). IIAR has designated the draft standard as BSR/IIAR 7-201x. Upon approval by the ANSI Board of Standards Review, the standard will receive a different name that reflects this approval date. We invite you to participate in the first (1st) public review of BSR/IIAR 7-201x. IIAR will use the American National Standards Institute (ANSI) procedures to develop evidence of consensus among affected parties. ANSI’s role in the revision process is to establish and enforce standards of openness, balance, due process, and harmonization with other American and International Standards. IIAR is the ANSI-accredited standards developer for BSR/IIAR 7-201x, and is responsible for the technical content of the standard. This site includes links to the following attachments: The 45-day public review period will be from November 10th, 2017 through December 26th, 2017. Comments are due no later than 5:00 pm Eastern Standard Time (EST) on December 26th, 2017. |

|

A quick review of the update shows no significant changes are necessary to the current stock templates.