There are a lot of choices out there for fixed Ammonia Detection these days. Common brands include CTI, Manning / Honeywell, Danfoss, Bacharach, Draeger, Hansen, and CoolAir.

Obviously if you are installing a new detector in a General Duty or PSM/RMP covered process, you want to perform an equipment-level PSSR (pre-Startup Safety Review) for the detector. However, a common question we get is “does changing from one brand to another require an MOC?”

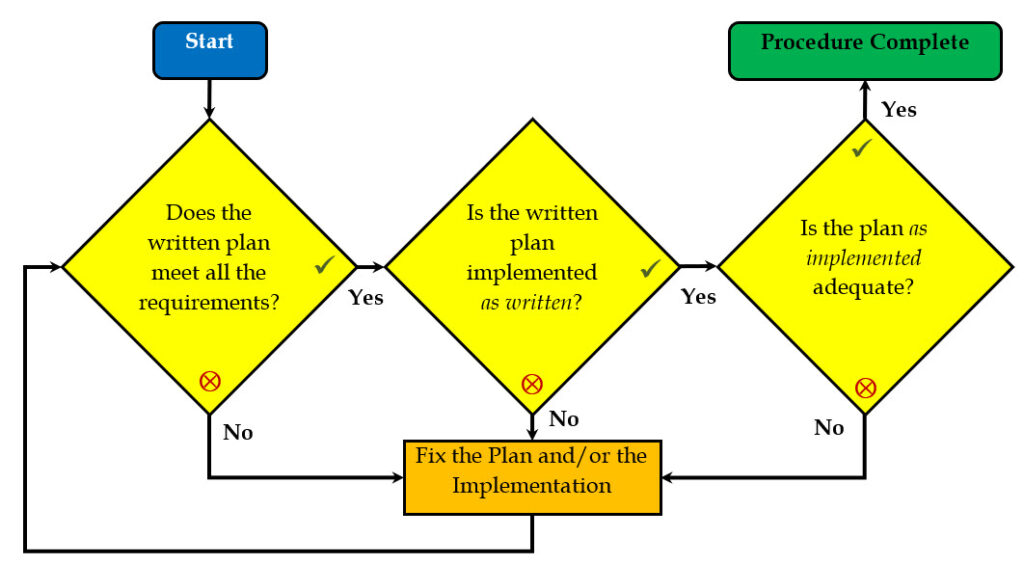

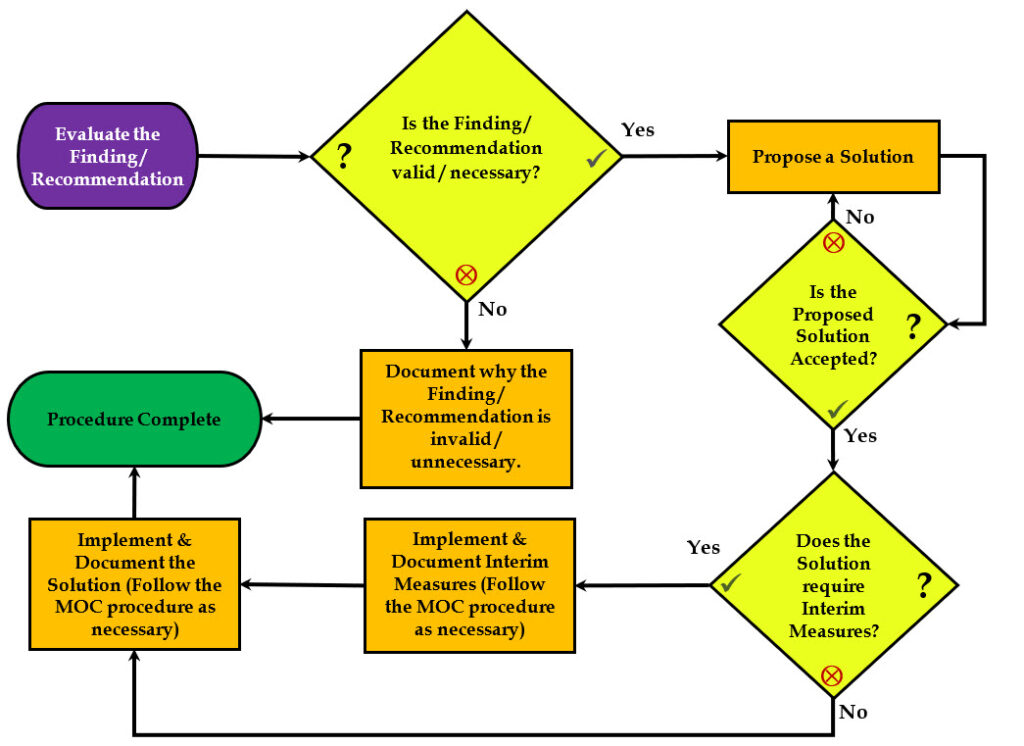

The root of this question is usually an attempt to justify the “change” as a “Replacement in Kind” and therefore avoid the paperwork of an MOC. But an MOC is not about PAPERWORK. An MOC is about thinking through the desired change (in a structured way) to see where problems can arise.

Put another way: Implementing the MOC procedure is how we answer the question of whether or not we need to document how we manage the change.

Let’s consider some things that might change when we replace one detector brand for another.

- Sensor Type.

- Sensor Range.

- Signal Type / Range.

- Enclosure Rating / Environmental Considerations.

- Detector Placement.

- Inspections, Tests & Maintenance.

- Bump Tests / Calibrations.

Sensor Type: Electrochemical, IR, Catalytic Bead, etc. Each of these types of sensors has benefits and drawbacks based on the conditions they are used for and in. If you are changing technologies, how does that change affect your process?

Sensor Range: Obviously the range of the sensor has an impact on how it works in your system. Replacing a 1-500ppm sensor with a 1-250ppm sensor without altering the system programming will report the wrong chemical concentration.

Signal Type / Range: Most sensor setups work on a 4-20mA signal, but some use Modbus or proprietary methods. You need to match your technologies or provide signal conversation.

Enclosure Rating / Environmental Considerations: Some sensors are subject to difficult environmental conditions such as blast-freezers and wash-down areas. You need to make sure that the sensor is suitable for the conditions you will expose it to.

Detector Placement: Manufacturer’s often provide recommendations on the height they want their detectors placed at. Make sure you are addressing those recommendations. If you are moving the Detector, are there any guarding considerations in the new location?

Inspections, Tests & Maintenance: Manufacturers have different inspections, tests and maintenance types and schedules. You must make sure you align to the manufacturers recommendations.

Bump Tests / Calibrations: Both the calibration method & frequency must be considered, including any unique calibration equipment and gases.

Conclusion: So, it’s possible that swapping a detector might well be a “Replacement in Kind” but there are a lot of things to consider before you arrive at that decision. You should use your MOC process to see if you need a formal, documented MOC.