First, what is a Repeat Citation? Here’s what OSHA has to say about it in their Field Operations Manual or FOM:

An employer may be cited for a repeated violation if that employer has been cited previously for the same or a substantially similar condition or hazard and the citation has become a final order of the Occupational Safety and Health Review Commission (OSHRC). A citation may become a final order by operation of law when an employer does not contest the citation, or pursuant to court decision or settlement. The underlying citation which the repeated violation will be based on must have become a final order before the occurrence or observation of the second substantially similar violation. (OSHA FOM Chapter 4, Section VII(A)(1). Pg. 4-21&4-22)

A Repeat violation is essentially exposing your employees to the same (or substantially similar) conditions or hazards after your company has previously been cited for the same (or substantially similar) conditions or hazards. Note that this is about your company and not your facility. If you are working for Billy Bob’s Cold Storage and they have four facilities, you may well be subject to a Repeat citation based on a citation issued at one of the other facilities. For Federal OSHA, the citation must have been made by Federal OSHA, not a state plan:

Federal Repeat Citations cannot be based on prior citations from State Plans (OSHA FOM Chapter 4, Section VII(A)(2). Pg. 4-22)

.

OSHA needs to establish three things to establish a Repeat violation:

- That the underlying condition or hazard is the same or substantially similar to one used as the basis for a previous citation.

- That the previous citation has been finalized – it can not be used to establish a Repeat violation if it is still being contested.

- That you actually came into compliance after the original citation.

.

Condition Substantially Similar:

They are issued based on similar conditions or hazards, not based on identical OSHA standard (OSHA FOM Chapter 4, Section VII(B) & VII(B) Pg. 4-22)

They CAN be issued for General Duty Citations (OSHA FOM Chapter 4, Section III(E). Pg. 4-18)

The key to understanding this is that it is NOT based on the particular OSHA Standard or Rule, it is based on the conditions / hazards. This is particularly important under PSM because a single condition or hazard may be cited under several different portions of the PSM Standard or Rule. As an example, let’s say that you were previously cited under PSM 29CFR1910.119(l)(5) for lacking an SOP for a new piece of equipment that was installed. The condition or hazard is not providing an SOP for a piece of equipment that operators are expected to operate. However, it’s important to note that the same condition or hazard could have been cited under 29CFR1910.119(e)(1), 29CFR1910.119(e)(3)(i), 29CFR1910.119(f), 29CFR1910.119(f)(2), 29CFR1910.119(f)(3), 29CFR1910.119(g)(1)(i), 29CFR1910.119(l)(2)(iii), 29CFR1910.119(i)(2)(ii), etc. Remember, it’s about the condition or hazard, not the individual OSHA rule.

.

Previous Citation is Final:

… the citation has become a final order of the Occupational Safety and Health Review Commission (hereafter,OS&H Review Commission). A citation may become a final order by operation of law when an employer does not contest the citation, or pursuant to court decision or settlement. The underlying citation which the repeated violation will be based on must have become a final order before the occurrence or observation of the second substantially similar violation. (OSHA FOM Chapter 4, Section VII(A)(1). Pg. 4-21&4-22)

While that seems like a minor legalistic issue, it’s one of extreme importance if you have been cited for an OSHA violation. Let’s imagine a situation where your facility is cited for a training issue. While you certainly want to address that issue as soon as possible, it may be wise to delay the settlement of the OSHA violation until you can address the same issue in your sister facilities as well. Settling quickly with OSHA may expose those sister facilities to Repeat violations.

.

You actually came into compliance after the first citation:

They are different from “Failure to Abate” citations. If an employer never came into compliance after an initial OSHA’s initial inspection / citation, that is a “Failure to Abate.” If the violation was corrected, and then later reoccurs, that is a Repeated violation. (OSHA FOM Chapter 4, Section VII(F) Pg. 4-23)

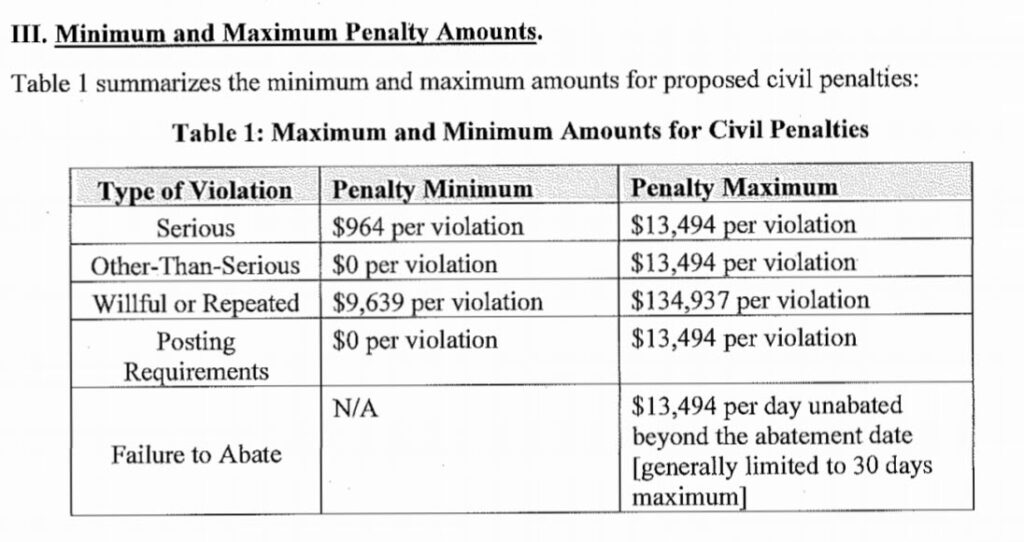

This is only really a matter of the associated fine. If the citation is Repeat, the fine is capped at about $129k. If the citation is actually a Failure to Abate, the fine is capped at $12.9k a day for up to 30 days or $387k.

.

Why are we seeing more Repeat citations?

Inspectors are being told to specifically look for these issues:

During inspections, CSHO’s must pay particular attention to identifying instances of Repeated violations from season to season or past occupancy. (OSHA FOM Chapter 12, Section II(F)(3) Pg. 12-3)

During the course of the ChemNEP inspection, the CSHO shall review abatement for all PSM citations issued within the previous six years to determine whether the hazard still exists. (OSHA CPL 03-00-021, Section XI(E)(10) Pg. 31)

.

What are the ramifications of a Repeat citation?

The fines can be up to $129,336 for each Repeated citation. (OSHA Act of 1970, Section 17) (OSHA Website on Penalties)

A single Repeat citation involving a fatality can place you in the Severe Violator Enforcement Program (SVEP). Two or more Repeat citations can place you in the SVEP if you have a “High Emphasis Hazard” as outlined in CPL 02-00-149 (which includes PSM facilities) (OSHA FOM Chapter 11, Section II(M)(2)(a) Pg. 11-13)

SVEP cases often spread to the entire region or even the entire country if the facility has sister facilities in other areas. OSHA may choose to inspect those other facilities or issue an abatement demand for ALL the sister facilities based on conditions found at SOME of them. Furthermore, OSHA “shall consider going beyond the subject of the citations to include additional safety and health program enhancements,” even for items that were not cited during the inspection. (CPL 02-00-152)

No reduction shall be given for repeated violations. If a repeated violation is found, no reduction for good faith can be applied to ANY of the violations found during the same inspection. (OSHA FOM Chapter 6, Section III(B)(3)(a) Pg. 6-7)

Each repeated violation is evaluated as serious or other-than-serious, based on current workplace conditions, and not on hazards found in the prior case. (OSHA FOM Chapter 6, Section V(A)(1) Pg. 6-11)

Repeat violations can be the basis of 11B enforcement action where the US Court of Appeals is asked to enforce the order. (OSHA FOM Chapter 15, Section XIV(B)(3) Pg. 15-14)

Obviously, there’s a lot of dollar signs involved, but that’s just the start of the possibilities. The real damage can come from becoming enrolled in the Severe Violator Enforcement Program or SVEP. The SVEP program is a nightmare that you want to avoid. I really can’t summarize it better than Eric Cohn did at OSHA Defense Report.

An employer is entered into SVEP at the outset of an OSHA case, prior to an opportunity to defend itself and prove wrong OSHA’s alleged violations. Notwithstanding this end run around Constitutional Due Process, once in the program, SVEP employers are immediately subject to:

- Public shaming by OSHA through both an inflammatory, embarrassing, and one-sided press release detailing the alleged violations and by posting the employer’s name on a Severe Violator list on OSHA’s public website;Severe Violator Image

- Mandatory follow-up inspections at that cited facility and up to ten sister facilities within the organization; and

- More expansive settlement terms than ever before, including corporate-wide requirements.

.

How far back can OSHA look for a previous citation to use as the basis for a Repeat?

Short answer – As long as they want. Long answer:

Although there are no statutory limitations on the length of time that a previously issued citation can be used as a basis for a repeated violation, it is OSHA policy that they are only to be issued withing five years of the final order date of the previous citation or within five years of the final abatement date, whichever is later, or five years from the issue of a final order from the OS&H Review Commision or final mandate from the US Court of Appeals. (OSHA FOM Chapter 4, Section VII(E)(1) Pg. 4-23)

-

Recent Court rulings have shown that since there are no statutory limitations on the Look-Back period, OSHA could issue Repeat citations based on citations older than five years. (OSHRC Triumph Construction)

-

Under OSHA Commission precedent, the “time between violations does not bear on whether a violation is repeated.” (OSHRC Hackensack Steel)

This long reach means that you need to know your history – and the history of your sister facilities.

.

While we certainly hope you never get cited by OSHA for a PSM violation, if it does happen, please don’t hesitate to contact us.

.

Sources: OSHA FOM, CPL 02-00-149 (SVEP), CPL 02-00-152, CPL 03-00-021, OSHA Act of 1970 (Judicial Review), OSHA Website on Penalties, OSHRC Triump Construction, OSHRC Hackensack Steel.