RAGAGEP is always changing and we have to ensure that our safety programs evolve to match the new / changed requirements. Tuesday I took a dive into NFPA 51B 2019, the standard for “Fire Prevention during Welding, Cutting, and Other Hot Work.” After reading through it, some changes were made to my base program. Here’s the section from my running “Change Log”

092419 – Updated both versions Hot Work Written Plans to deal with NFPA51B-2019.

- Changed NFPA references to match new section numbers

- Changed fire watch to 60-minute minimum per NFPA.

- Updated master definitions file (in \01-RMP\ ) to include updated definition of Fire Watch and new definitions for Fire Protection System and Fire Monitoring.

To Implement:

- Change out \01 – EPA RMP\Definitions – Glossary of Terms and Acronyms with 092419 version by using the appropriate MOC procedure.

- Replace \09 – Hot Work\09 – Hot Work Permit Element Written Plan with 092419 version by using the appropriate MOC procedure.

- Train all personnel involved in Hot Work about new 60-minute fire watch requirement. Document training per the written plan.

This is a fairly simple change. You may have noticed that there is a new section in the “Change Log” for each entry – a “To Implement” section that tells you how to modify your program if it was written based on the baseline templates. I’ve gone back through the last month’s changes and added this information. Time willing, I might do the same for the previous 100+ entries!

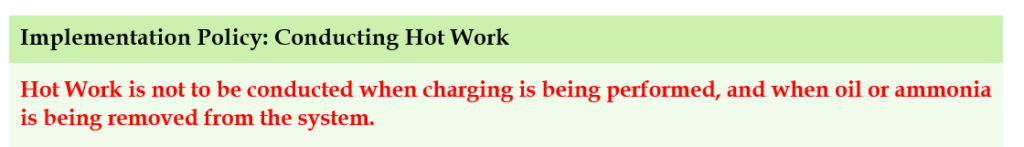

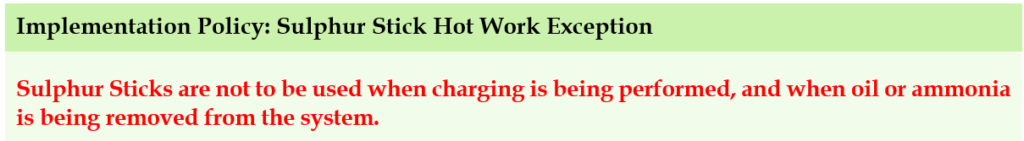

While we are on the subject of Hot Work though, I want to bring up another common issue: “Designated Areas.” This is a particularly “Hot” topic right now, because a recent large industrial fire was caused by Hot Work and some people are saying it was an oil fire caused by Hot Work done in a “shop.”

Designated Areas: Many plants have “Designated Areas” such as maintenance or welding shops where Hot Work is conducted without the use of a permit. It should be noted that nothing in the PSM/RMP or OSHA General Industry rules (as interpreted through 1910.119(k)) appear to support this. For this reason, we’ve always called these areas “Magic Rooms” because people seem to think that these rooms are exempt from OSHA rules. The custom actually comes from NFPA 51B:

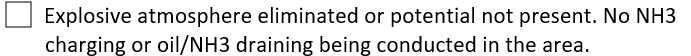

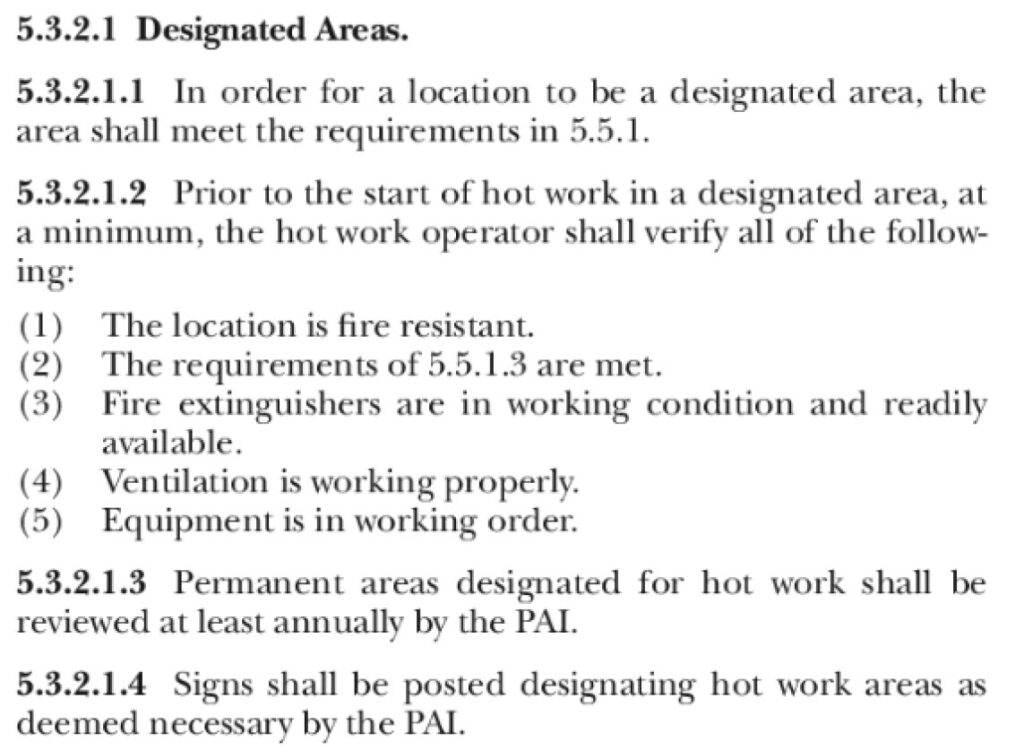

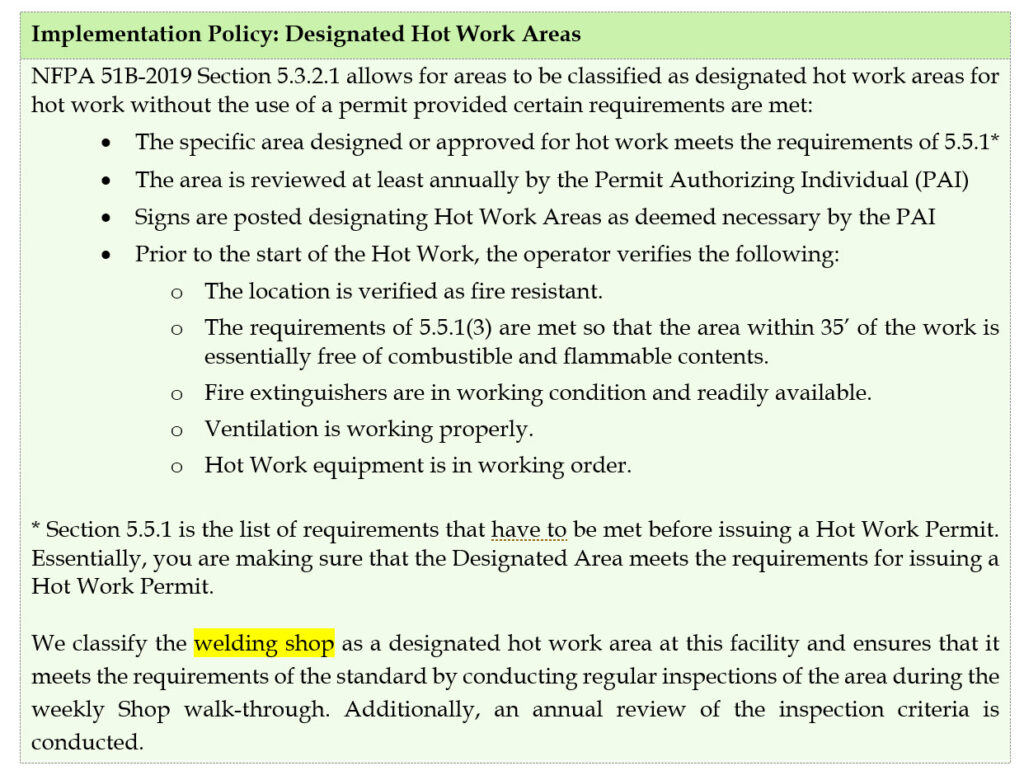

In the 2019 version, it is section 5.3.2.1 which allows for areas to be classified as Designated Hot Work areas. These areas would allow Hot Work without the use of the written permit provided certain requirements are met:

- The specific area designed or approved for Hot Work meets the requirements of 5.5.1*

- The area is reviewed at least annually by the Permit Authorizing Individual

- Signs are posted designating Hot Work Areas

- Prior to the start of the Hot Work, the operator verifies the following:

- The location is verified as fire resistant.

- The requirements of 5.4.2(3) are met so that the area is essentially free of combustible and flammable contents.

- Fire extinguishers are in working condition and readily available.

- Ventilation is working properly.

- Hot Work equipment is in working order.

* Section 5.5.1 is the list of requirements that have to be met before issuing a Hot Work Permit. Essentially, you are making sure that the Designated Area meets the requirements for issuing a Hot Work Permit without actually issuing one.

The acceptability of this custom is in question due to a statement made by OSHA in their PSM Preamble:

“…this proposed provision would not require a permit for Hot Work operations in a welding shop unless the welding shop was located in a process area covered by the standard. OSHA believes that such a location would not exist.” (OSHA, PSM Preamble, 1992)

OSHA was clearly thinking of Petroleum and Chemical plants in that quote, where such situations are usually not found. As of 2019, we are not aware of any Ammonia Refrigeration PSM-covered facility receiving a Hot Work citation for Designated Areas if they follow the requirements of NFPA 51B Section 5.3.2.1. Still, it would be far more defensible if you issued Hot Work permits for all Hot Work, even that work conducted in maintenance and welding shops.

Here’s a look at the Hot Work element Written Plan section dealing with Designated Hot Work Areas:

Note: Previous discussion on Hot Work at this link. You can read the 2019 version of NFPA-51B in its entirety at NFPA.org