Disclaimer: This post is a collaboration between an industry friend and colleague, Victor Dearman and I. The views expressed here do not necessarily represent the opinions of any entity whatsoever which we have been, are now, or will be affiliated.

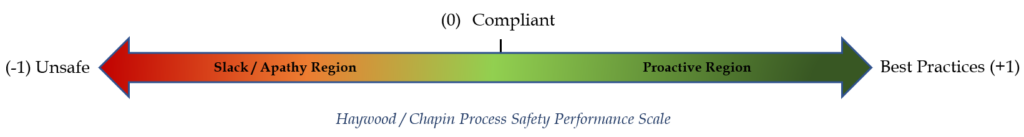

It’s a question we hear often – sometimes as part of a PHA or Compliance Audit, but more often with someone just struggling to justify their staffing requests. Unfortunately, there really isn’t a simple, definitive answer to the question. No controlling RAGAGEP exists and state / local laws on the topic are relatively rare. This sort of problem isn’t rare in PSM because it is a performance-based standard. Our performance basis is that we are staffed sufficiently to ensure the safety of the people within the building and the surrounding community.

We need to answer the “How many Operators do we need?” question in a way that we can support it, or as we like to say, “Build a defensible case for the answer we arrive at. The answer itself will depend on many, many factors. So, let’s go on a journey and see how we can arrive at an answer we can feel confident in.

The road to an answer

The biggest factor for many is the design (age!?) of the system controls. A modern system with advanced controls requires less oversight on a day-to-day basis. If your system still relies on manual controls and people writing down pressures every hour, then that’s going to have a significant impact on your staffing needs. But once we get past that obvious issue, things get a bit more complicated.

Let’s be honest here, if things are running well; you have a good history with compliance audits, inspections, incident investigations, etc. and a low MI backlog, you’re probably not asking this question. If you are asking this question, it is probably due to an event related to a PSM/RMP element.

Let’s look at the kinds of element events that typically lead to this question.

- Employee Participation

- Mechanical Integrity

- Incident Investigations

- Management of Change / Pre-Startup Safety Review

- Process Hazard Analysis

- Emergency Action and Response Plans

Employee Participation: Look, everyone feels over-burdened at work, especially in the modern “Do MORE with LESS” era. But, if you pay attention to it, and look at these other elements, this employee feedback can provide valuable insights into the adequacy of your staffing.

Mechanical Integrity: What we’re looking for here is to understand if you have the skill sets and staffing to adequately maintain your refrigeration system. Whether you do everything in-house, or have a small in-house small crew performing basic rounds and contract out all the rest of the maintenance, inspections, and tests, is it adequate?

Here’s some MI related questions you might ask to help you determine if your staffing is adequate:

-

- Are we properly implementing our Line & Equipment Opening (sometimes known as line break) procedures?

- Are we caught up on ITPMR’s (Inspection, Test and Preventative Maintenance Reports) or work orders?

- Is the documentation of ITPMR’s, Work orders, Oil Logs adequate?

- Are we performing our scheduled walk-through’s and documenting them properly?

- Are we addressing MI recommendations in a timely manner?

- Are there indications that maintenance of the facility and system are being conducted properly and required repairs aren’t being delayed?

- Are there no indications in the written MI records, or in your observations, that the system is running outside the written operating limits?

Incident Investigations: A review of incident investigation history can tell us a lot if the facility has a good process safety culture. But if they don’t have the right culture, and /or they don’t have any documented incidents, you’re going to have to do a little detective work and interview plant employees to find out if incidents are occurring that aren’t being recorded. Remember to spread your net wide here because incidents can happen at any time, not just on day-shift: Backshifts, weekends, holidays, etc. there’s no time immune to a possible incident.

You may also find indications of incidents occurring in walk-through logs, communications logs, ITPMRs, work orders, etc.

Here’s some II related questions you might ask to help you determine if your staffing is adequate:

-

- Are incidents being reported, conducted, and documented? If not, is this a culture issue or a staffing issue?

- Are incidents and incident report findings & recommendations being addressed, communicated, and followed to their conclusion?

- Are there incidents that could have avoided with proper staffing?

- Are there incidents that would have their severity reduced with proper staffing?

- Are there incident investigations with recommendations that could be addressed with proper staffing?

Management of Change / Pre-Startup Safety Review: Properly implementing the MOC and PSSR elements takes a lot of time! We often find that these two elements are amongst the first to “fall behind” in suboptimal staffing situations. Here’s some MOC/PSSR related questions you might ask to help you determine if your staffing is adequate:

-

- Have MOCs / PSSRs been conducted when they were supposed to be?

- Were the MOCs / PSSRs conducted adequately to properly manage the hazards related to the change and the new systems?

- Is the documentation of MOCs / PSSRs complete?

- Are there any open items or recommendations from MOCs, PSSRs, or project punch lists?

Process Hazard Analysis: The PHA and open PHA recommendations can also help us understand if our staffing levels are appropriate. There may also be indications in the PHA itself. There’s a portion of the PHA that deals with staffing directly, but we’ll deal with that in the Building a defensible case on staffing section of this article.

Here’s some PHA related questions you might ask to help you determine if your staffing is adequate:

-

- Are the PHA recommendations being addressed, communicated, and followed to their conclusion?

- Is the facility provided with modern controls, alarm systems and equipment? (Newer, modern facilities often have significantly lower staffing needs than older ones)

- Has the PHA been updated / validated as required by MOC activities and the 5yr schedule?

Emergency Action and Response Plans: Whether we’re looking at the plan(s) themselves, or analyzing an after-action report, a there can be a lot to learn here concerning proper staffing levels. Obviously, the required staffing levels for Emergency Response facilities is going to be higher, but that doesn’t mean there is no staffing requirement for Emergency Action plans.

Here’s some EAP/ERP related questions you might ask to help you determine if your staffing is adequate:

-

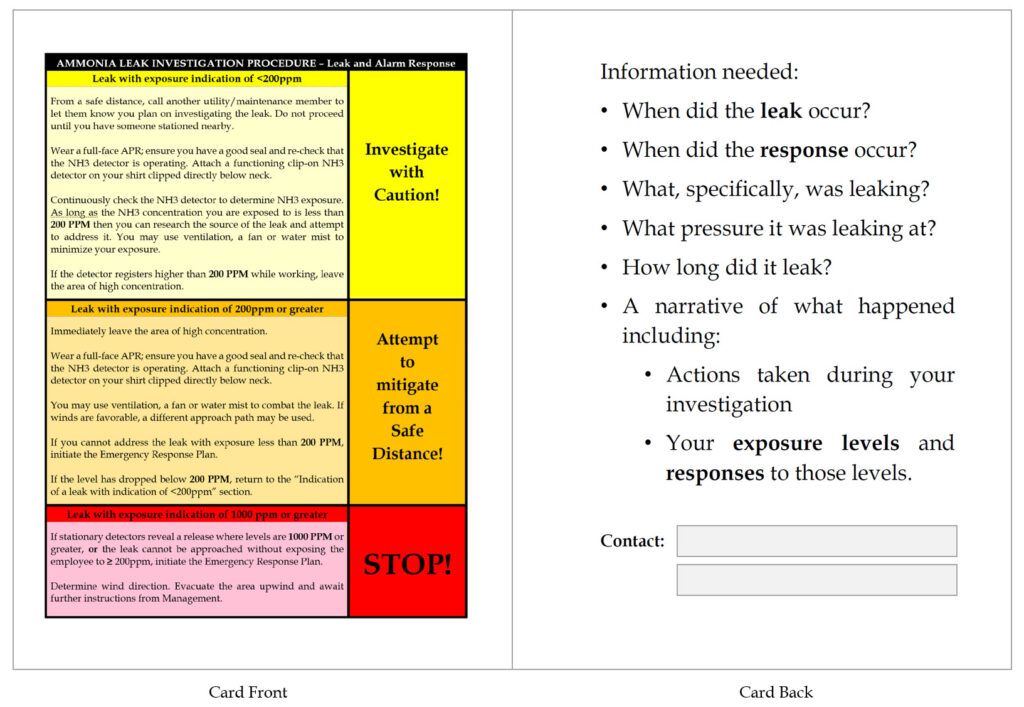

- In the event of an incidental release of ammonia, do you have adequate staffing to investigate and respond?

- In the event of an emergency response, even if you are not a “responding” facility, do you have adequate staffing to ensure that the equipment is properly shut down?

- If you are a “responding” facility, do you have enough adequately trained personnel to staff your response team including an Incident Commander, safety officer, decontamination personnel, two entry teams, etc.

- If you bring key staff back on-site to deal with emergencies, are they close enough to respond in a timely manner, or do you need to increase the size of your trained response team?

Building a defensible case on staffing

Ok, we’ve answered our questions and gathered a good impression of where we stand – and where we should stand. Maybe we need to adjust our staffing levels and/or increase the amount of services we ask contractors to complete for us. Where should we document this? In our opinion, the place in the system where the facility already had the opportunity to address this issue, was in the PHA. So, let’s go back to the PHA, end see if our results match the PHA team’s.

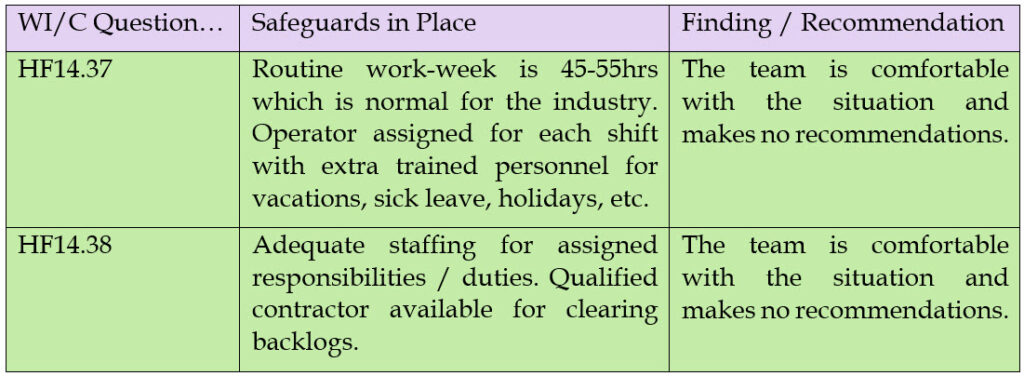

You are going to be looking for the following two questions (or their equivalents) from the standard Human Factors section of the IIAR What-If /Checklist worksheets:

HF14.37 – What if an employee is stressed due to shift work and overtime schedules?

HF14.38 – What if there are not sufficient employees to properly operate the system and respond to system upsets?

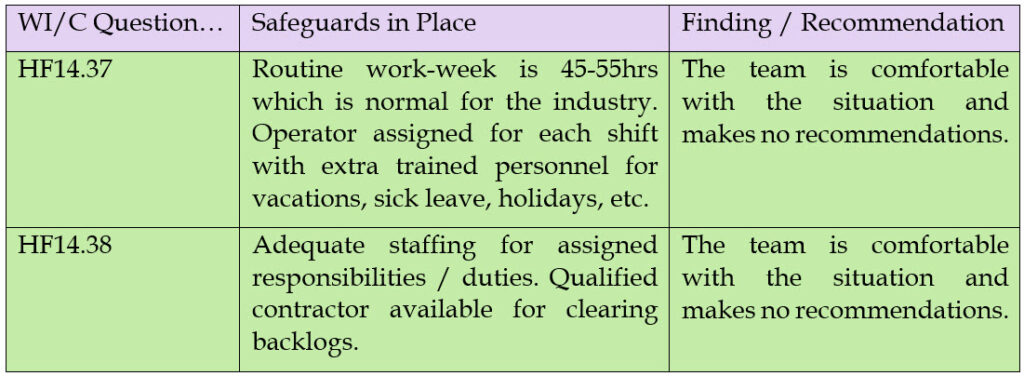

During the PHA, the facility should have answered those in a way that says they have adequate staffing or recommended that staffing be increased. Let’s say you decided that you had adequate staffing based on your answers to the questions above. If that’s the case, we’d expect to see something like the following:

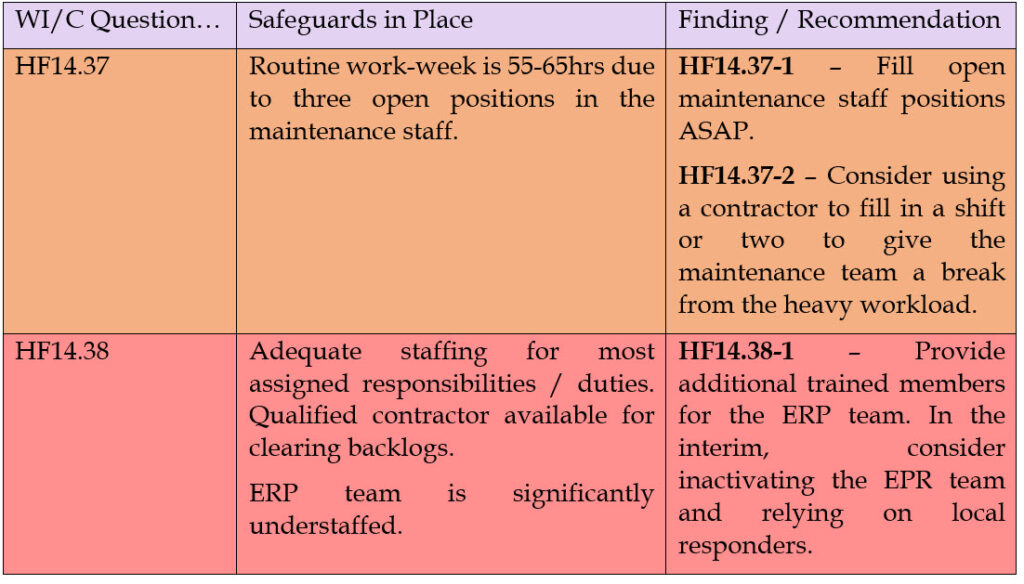

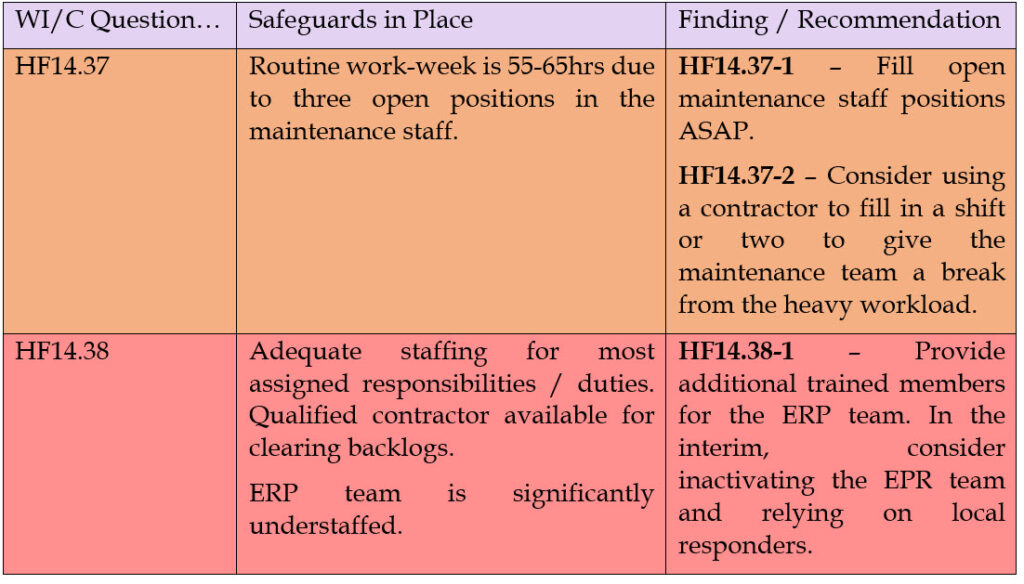

If, however, we found some areas for improvement, we might expect something like this:

Closing Thoughts: We hope you didn’t start reading this hoping for an easy answer, but we’re fairly certain – now that you understand the full scope of the question being asked – that the answer doesn’t need to be easy, it needs to be correct and defensible.

You can build a much better understanding of your staffing needs by looking at the existing elements in your Process Safety program. Any decent Compliance Audit would cover this same ground, if staffing is an area of concern for you, make sure to bring it up.

—

P.S. from Victor: Some facilities might try and get more value from a security guard on off shifts or holiday coverage to make roving patrols and report abnormal conditions and alarms? Sure, but that also means that guard has to be trained to identify what the alarms mean, how to identify an abnormal condition, and that they know what to do to either immediately correct the deviation or immediately contact someone that can (on call techs or service providers). By the time you have invested this much into a guard, you could have paid for a well-qualified operator.

My advice to any organization when making these decisions is to evaluate the above and take into consideration the attracting well rounded operators with the skill sets and experience often sought is more often through word of mouth about how the organization projects their Process Safety culture.

How to hire operators? Well, that sounds like a good subject for a future article!