Both OSHA’s PSM and the EPA’s RMP rule require a Compliance Audit of your Process Safety program at least every three years. That Compliance Audit is meant to ask some very important questions:

- Is the required PSM/RM Program in place?

- Are the practices of the facility consistent with the required PSM/RM Program?

- Does the required PSM/RM Program as it is written and implemented effectively control the covered process and its hazards?

Have the experts at RC&E assist you in performing this required audit. Here’s what we bring to the audit process:

Less Business Impact: Our typical PSM/RM Program audit lasts two days or less so your personnel can get back to work as quickly as possible.

Knowledge: Our compliance personnel are entirely focused on compliance with PSM/RMP and have been for over a decade. They’ve seen hundreds of processes just like yours and can suggest the approach that may work best for your situation. Identified issues will include the specific regulatory, code or RAGAGEP reference so you know the issue is a legitimate one rather than an auditor’s opinion.

Proven Methods: Our audit process combines three regulatory audit processes into a single cohesive compliance audit:

EPA RMPL3 – The EPA’s Level 3 Risk Management Plan/Risk Management Program checklist

OSHA PQV – OSHA’s Program Quality Verification checklist including document inspection, on-site conditions and interviews.

OSHA ChemNEP – Specific questions that have appeared during OSHA’s Chemical National Emphasis Program inspections.

We combine these three approaches to provide a comprehensive audit that will include not only the specific deficiencies in the program and/or its implementation, but suggested strategies and industry best practices to solve those problems.

Teamwork: Our focus is on whether it meets the requirements of the PSM/RMP rules in a way that works for YOUR facility. Our compliance personnel always review draft findings and recommendations with your personnel during the audit to ensure they fully understand the issue and the possible solutions. We won’t just point out problems – we will provide solutions. Every deficiency we find in our audit will include a specific suggested solution to that deficiency. In many cases, we will provide multiple suggestions allowing the facility to choose the method of addressing the issue that best suits their unique situation.

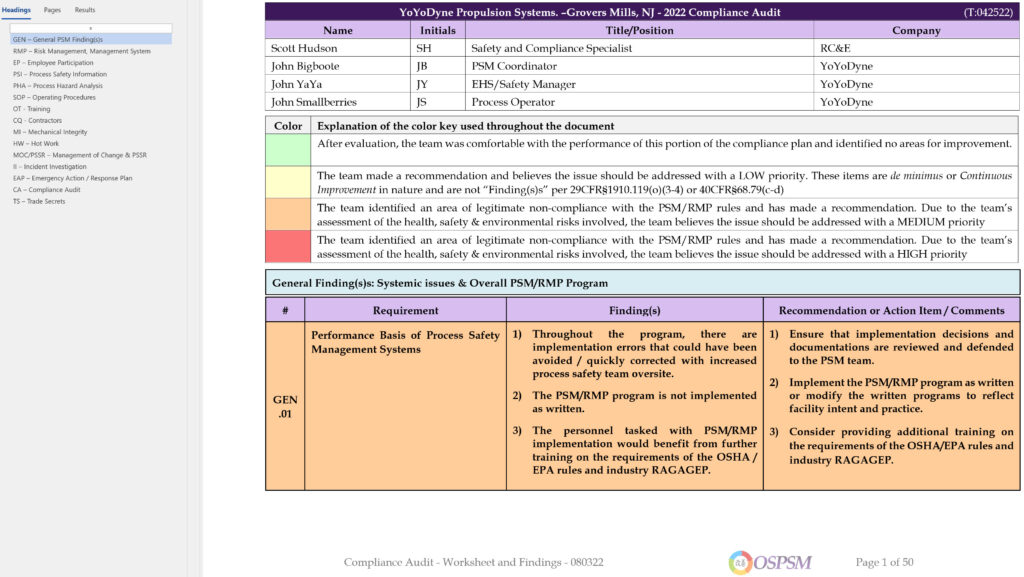

Compliance Audit Page Example – General Process Safety

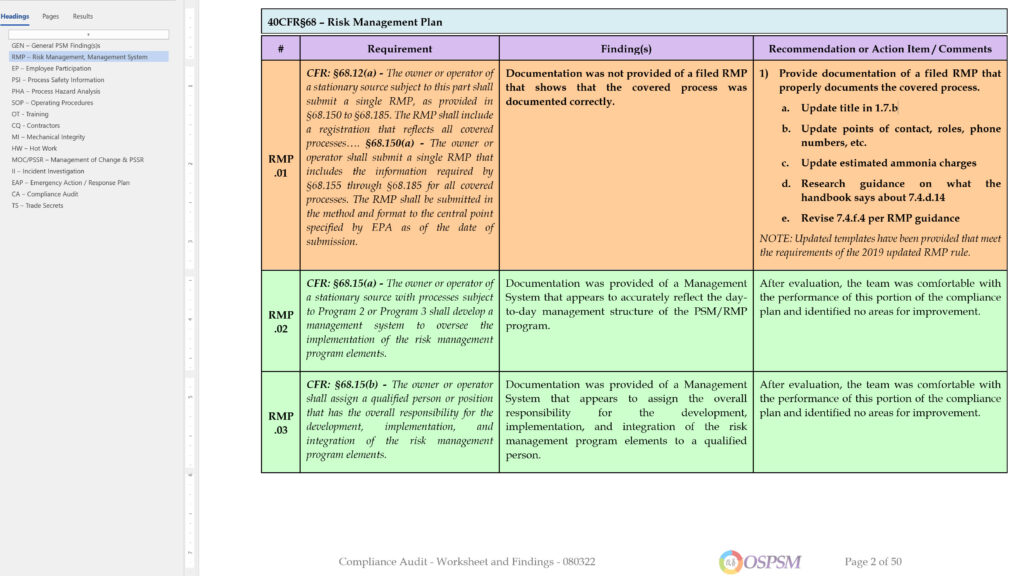

Compliance Audit Page Example – Risk Management Program

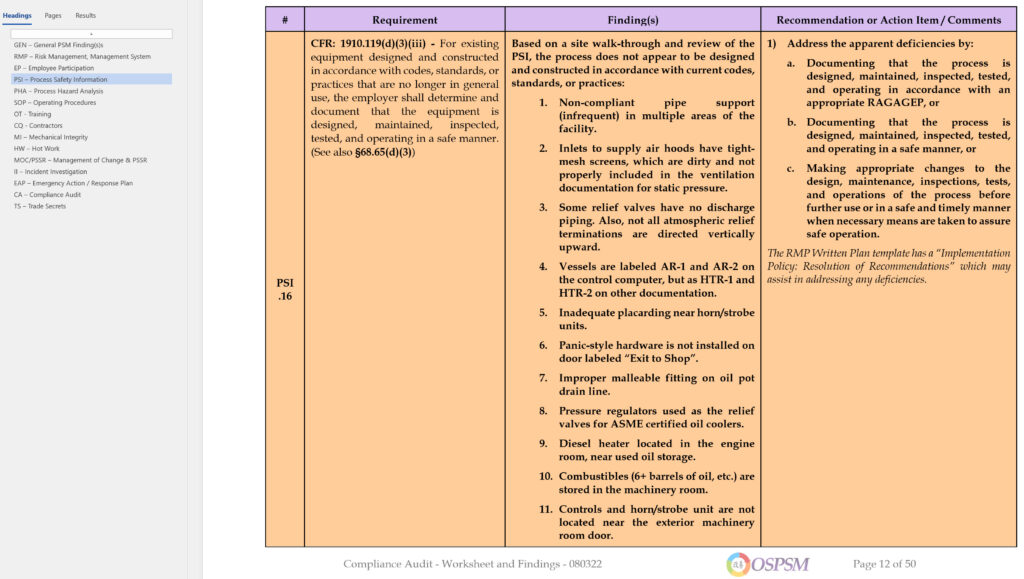

Compliance Audit Page Example – Process Safety Information

Follow-Through: Our commitment to you doesn’t end when we leave the site; we always remain available to answer questions and assist with corrective actions to recommendations.

Email or call us today to have RC&E assist you with all your PSM/RM Program needs! [email protected] (888) 357-COOL (2665)

For a convenient PDF of this information Click Here.